Smart Personalization: Antigro Designer and Inkcups Helix ONE

The ability to personalize a wide variety of products—especially custom drinkware—brings immense value to customers, who increasingly seek unique, personalized options when shopping online. Today’s buyers expect e-commerce stores and print businesses to offer tools that let them create custom designs and receive high-quality prints as quickly as possible.

However, meeting these expectations can be challenging without the right technology and software to support it. That’s why having reliable solutions is essential. Thanks to the seamless integration between Antigro Designer software and the Inkcups Helix One printer, print shops can streamline their operations and produce stunning, personalized items faster than ever before, achieving turnaround times that once seemed impossible.

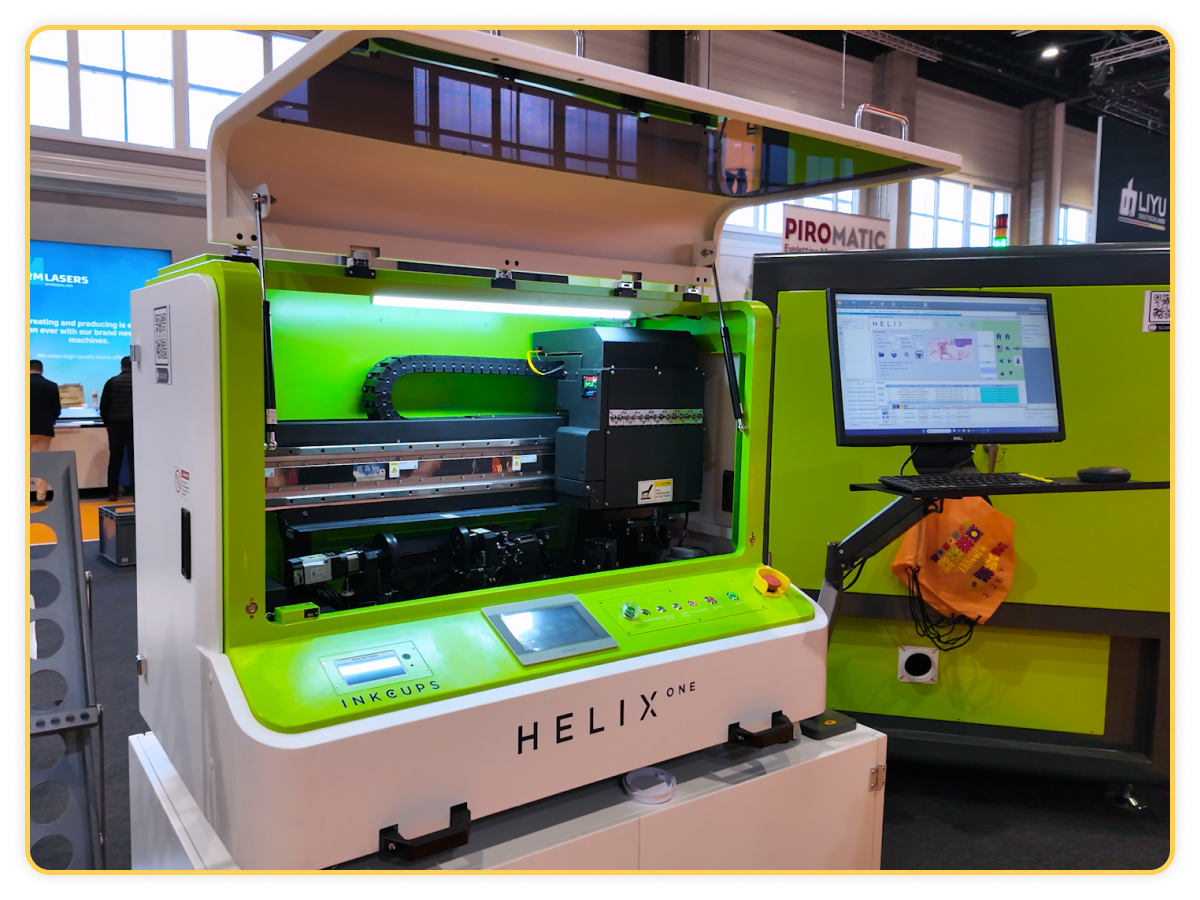

Inkcups Helix One Printer - Technical Specifications

The Inkcups Helix ONE printer is a compact device designed for 360° printing on cylindrical objects such as bottles or candle holders, with diameters ranging from 45–116 mm and lengths from 51–310 mm. It features a precise, motor-driven rotary table with automatically programmable clamping and height adjustment, ensuring perfect positioning of the object. MEMS printheads produce droplets with a volume of 3 picoliters, enabling high-quality graphics at resolutions up to 600 × 1200 dpi. The Helix ONE supports simultaneous printing in CMYK + white + varnish configuration thanks to its segmented 8 W UV lamp, which allows for white underprinting and graphic protection, among other functions. Additionally, the device includes an automated printhead cleaning station and liquid stirring systems in the ink sub-tanks (white and black sub-tank stirring system), enhancing reliability and printing stability. The dimensions of the Helix ONE are 1227 × 825 × 950 mm, and it weighs approximately 295 kg (650 lb).

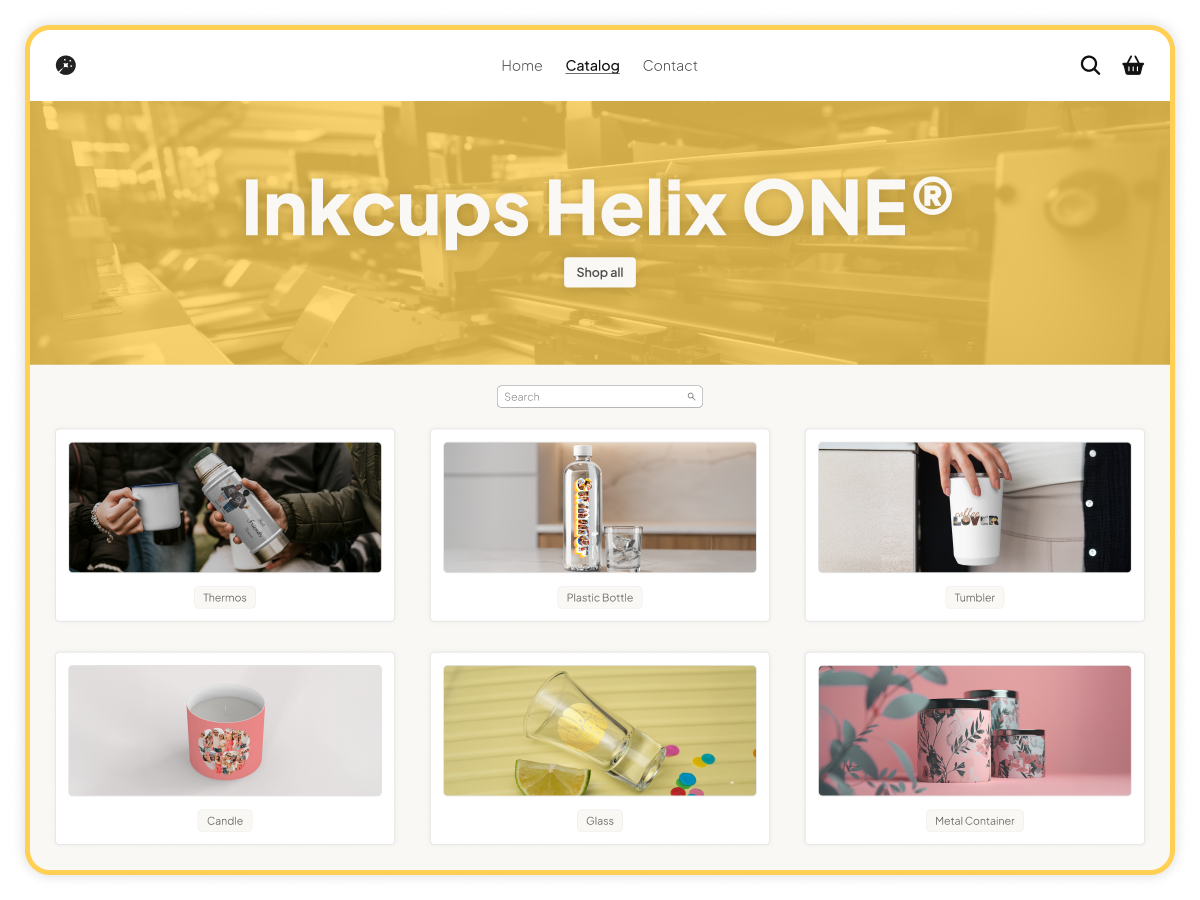

Products You Can Sell with Antigro Designer and the Inkcups Helix One Printer

With the versatile capabilities of the Antigro Designer print customizer and the Inkcups Helix One printer—which can print directly onto cylindrical objects like bottles or candle holders, accommodating diameters from 45–116 mm and lengths from 51–310 mm—the creative possibilities provided by this duo are virtually limitless.

The seamless integration of the Antigro Designer print customizer with the Inkcups Helix One printer opens up vast opportunities for producing a diverse range of personalized products. It enables the creation of high-quality drinkware items such as thermoses, plastic bottles, tumblers and shot glasses. Additionally, the Helix One allows for customization of other objects like candle holders, metal containers with decorative patterns, food containers, and various other cylindrical products. This makes it an ideal solution for companies specializing in gift production, promotional merchandise, decorative items, as well as for print shops and e-commerce businesses offering customized products.

Custom Drinkware Without the Hassle: Smooth File Prep and Workflow

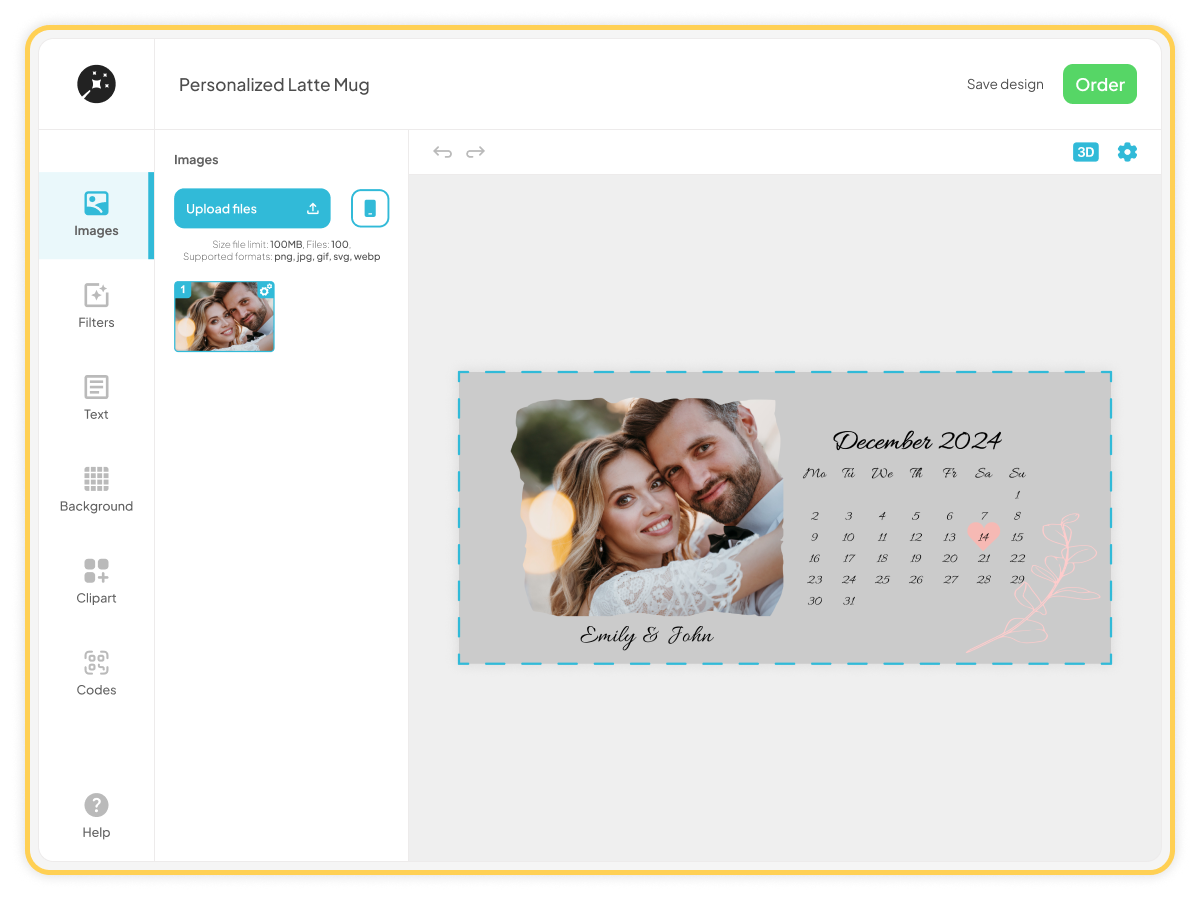

Creating personalized products with the Antigro Designer Print Customizer is easy and intuitive, whether customers are working from a desktop or a mobile device. After choosing a product in the online store, they’re taken to the Antigro Designer interface, where they can design items such as bottles, glasses, and many other products. Users can either start with editable templates or design from scratch, utilizing a broad set of customization tools—including text, photo filters, clipart, QR codes, and templates featuring dynamic fields.

One of the key features that makes it possible to create advanced products without errors in visualization—and ensures that the final product meets customer expectations—is the real-time 3D preview, which allows users to clearly see how their finished item will look, boosting confidence and satisfaction throughout the design process. This functionality is especially vital for drinkware and other three-dimensional products where precise visualization is critical.

Once an order is finalized and payment is processed, the system automatically generates print-ready files precisely configured for the Inkcups Helix One printer. These files include all necessary elements, enabling a fully automated workflow without the need for manual file preparation. Furthermore, they can incorporate customer-specific data, helping print shop staff efficiently organize, sort, and prepare items for shipping, resulting in a production process that is fast, accurate, and highly scalable.

Inkcups Helix One and the Antigro Designer Workflow in Action

During FESPA 2025, Antigro Designer, in collaboration with Inkcups, showcased a live demonstration of how personalized latte cups are created. Visitors had the opportunity to design unique graphics themselves using the Antigro Designer Print Customizer, taking advantage of advanced personalization features. The designs were automatically converted into print-ready files and printed on-site with the Inkcups Helix® ONE printer.

During the event, nearly 200 participants created their own designs on latte cups, which were printed live. This demonstration perfectly illustrated how the combination of smart design tools and high-performance printing technology enables the production of personalized, high-quality drinkware products.

Request a demo to transform your printing business

Join the printing revolution trusted by hundreds of companies worldwide.